Forage Quality: The True Triple Mower Advantage

With today’s advanced technologies, grain harvesting has become a pretty straight-forward process. Wait for the right crop conditions, catch a little break in the weather, then set your combine for the right crop and let the satellites, sensors, and algorithms do their thing! (OK, maybe it's not THAT straight-forward!)

Forage harvesting, on the other hand, is a completely different endeavor. Everything you do, from the first cut to the final bale, makes a huge difference in the nutritional value and profitability of your crop. The timing, technique, and tools that are used all positively or negatively affect the outcome of an entire season’s worth of work. Are you getting the most out of yours?

Timing:

Forage harvesting is a process that takes days not hours. It requires a long weather window and just the right timing to retain peak nutritional values.

According to Dr. Dan Undersander and Craig Saxe of the University of Wisconsin Extension, the key to quality forage begins with a quick dry-down. The cut forage crop continues to lose nutritional value through plant respiration until it dries to 60% moisture. The quicker you can get moisture down to that level, the more nutritional value is retained.

Technique:

According to Dr. Undersander, “A wide swath after cutting is the single most important factor for maximizing initial drying rate and preserving starches and sugars.” Studies conducted by Saxe and Undersander suggest that higher crop quality RFQ (starch and sugar) can be attributed to a wider windrow width. They recommend laying the crop in the widest windrow possible, with more than 70% cut width being good and greater than 90% being ideal.

Tools:

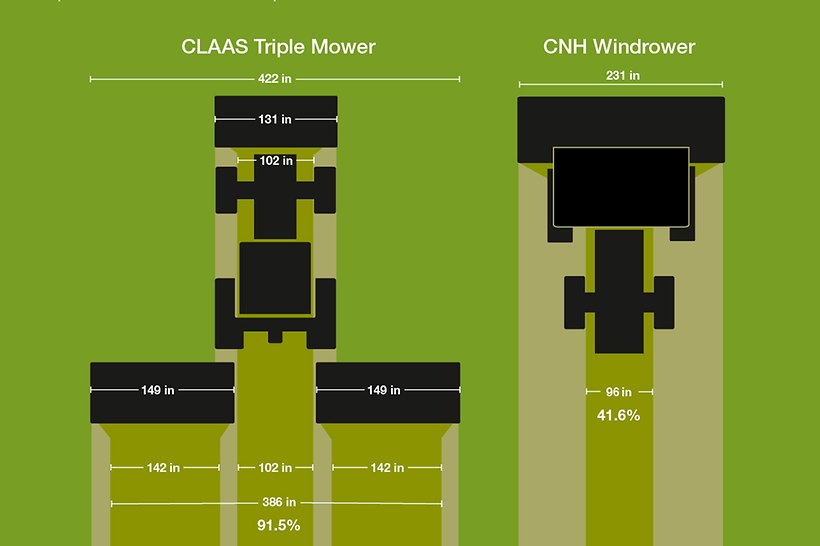

To produce the exceptionally wide windrows needed for quick dry-down, a triple mower is really your only tool of choice. Self-propelled windrowers are designed to cut the crop in front of the machine and narrow the swath so the machine wheels don’t run over the cut crop. The wider the cutter bar, the more the total width is narrowed to pass cleanly underneath the machine. This design flaw requires tight, narrow windrows leading to a longer dry-down period and lost nutritional value.

CLAAS triple mowers consist of a front mower just wider than the edges of the tires of the tractor and two wing mowers in the back. Because the wing mowers are operating behind the machine there is no need to compress the windrow. The result -- swaths greater than 90% of the cut width – and often twice the width of a self-propelled windrower.

CLAAS Triple Mower v. CNH Windrower

| Cutting Units: | DISCO 3600F and DISCO 1100 | CNH RD193 | CLAAS Advantage |

| Power Units: | AXION 940 Tractor | CNH Windrower WD 2504 | |

| Cutting Width: | 422" | 231" | 191" |

| Windrow Width: | 386" | 96" | 290" |

| % of Cut Width: | 91.5% | 41.6% | 49.9% |

| Expected RFQ: | 172.21 | 156.28 | 15.93 |

Of all the reasons to buy a CLAAS triple mower – throughput, tractor-driven versatility, fuel efficiency, and cut quality – the most important reason of all just might be the surprising nutritional quality difference.

- Undersander, D. In Proceedings, 2008 California Alfalfa & Forage Symposium and Western Seed Conference, San Diego, CA, 2-4 December, 2008. UC Cooperative Extension Plant Sciences Department, University of California, Davis, CA 95616

- Undersander, D., & Saxe, C. (2013). Field Drying Forage for Hay and Haylage (pp. 1-2, Tech.). Madison, WI: University of Wisconsin Board of Regents.

- Undersander, D. (2015, June 2). Wide swaths work for both hay and haylage. Retrieved February 22, 2021, from https://www.hayandforage.com/article-25-%20wide-swaths-work-for-both-hay-and-haylage.html

Event calendar

-

DateEvent

-

Jul 25, 2024 - Jul 25, 2024Baltic, SD

-

Aug 27, 2024 - Aug 29, 2024Boone, IA

-

Jul 16, 2024 - Jul 18, 2024Saskatoon, Saskatchewan