Head-to-Head with the Latest PICK UP from CLAAS

We recently put the latest CLAAS PICK UP header technology to the test in a triticale field against the best that John Deere and New Holland had to offer. In a side-by-side comparison of horsepower-equivalent CLAAS, John Deere and New Holland forage harvesters, the CLAAS JAGUAR with its new variable speed PICK UP (PU) header drive performed better overall in capacity and fuel economy. The capacity advantage was especially noticable at longer cut lengths.

Key Outcomes

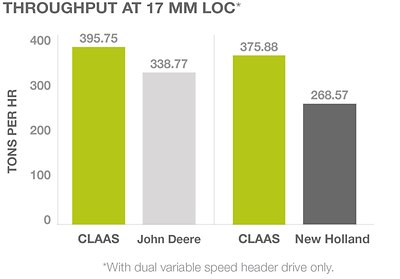

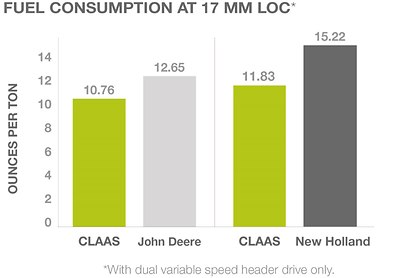

- The CLAAS JAGUAR 990 saw 17% more tons/hr. and 18% less fuel/ton vs. John Deere at 17 mm LOC.

- The CLAAS JAGUAR 990 was 29% more fuel efficient than New Holland and achieved 40% more capacity at 17mm LOC.

- The CLAAS dual variable speed drive has significant advantages over the 100% mechanical drive depending on crop conditions.

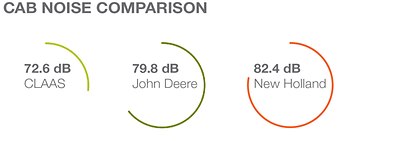

- The CLAAS JAGUAR 990 was significantly quieter than competitive machine cabs

The Comparison Process

Machines Compared:

- CLAAS JAGUAR 990 (925 hp) + PU 380 dual hydraulic

- CLAAS JAGUAR 990 (925 hp) + PU 380 mechanical

- John Deere 9900 (970 hp) + 649

- New Holland FR920 (911 hp) + 380FP

Our Approach

Each forage harvester was setup and run by an experienced machine operator. All machines were run on the same days in the same fields in California. The machines were run at groundspeeds between 3-7 mph while harvesting winter forage at 66-72% moisture. All tests against competitive machines included the variable speed header drive only. All loads were timed and weighed on a scale. Fuel consumption was weighed with a fuel metering system after each truck.

Hydraulic vs. Mechanical

The variable speed header drive offers significant improvements for both throughput and fuel efficiency. The first segment of the tests included two CLAAS JAGUAR 990 machines running side-by-side -- one with mechanical drive and one with dual hydraulic. The forage harvester with variable speed drive saw an increase in capacity. Why? In varying ground speed and field conditions, the dual variable speed header drive offers fine-tuned settings from the cab to work in differing landscapes.

Tons Per Hour

The dual variable speed header drive performed better than competitive brands. Operated side-by-side with the John Deere 9900, the CLAAS JAGUAR saw 17% more capacity at a 17 mm LOC. It also saw a significant 40% increase in capacity compared to the New Holland forage harvester. Why? The dual variable speed header drive adjusts the speed of the pick-up tines independent of the auger and matches ground speeds, synchronizing the auger to LOC for constant crop flow and optimal chop quality. Coupled with the transverse engine for direct drive and straight crop flow, there is a significant capacity increase over competitors.

Fuel Per Ton

The dual variable speed header drive outperforms competitive brands in fuel efficiency. The CLAAS JAGUAR consumed 29% less fuel than New Holland and 18% less fuel than John Deere at 17 mm LOC. Why? The crop is accelerated at each step and is centered by the chevron arrangement of the knives and accelerator paddles. This means maximum performance with minimum power consumption. The transverse engine also creates better fuel economy than competitive brands.

Quiet Cab

The CLAAS JAGUAR cab is quieter than competitive brands. For every 3 dB increase, sound energy is doubled. The National Institute for Occupational Safety and Health (NIOSH*) recommends that exposures to noise should be controlled below 85 dB to minimize occupational noise-induced hearing loss. The CLAAS JAGUAR generated 7 dB less than John Deere and 10 dB less than New Holland. Why? A double-paned front window, pillar in the rear window, extra insulation in the floor, as well as special coating around the knife drum area absorbs sound for a much quieter cab.

*According to the National Insitute of Occupational Safety and Health (NIOSH) website.

Event calendar

-

DateEvent

-

Jul 25, 2024 - Jul 25, 2024Baltic, SD

-

Aug 27, 2024 - Aug 29, 2024Boone, IA

-

Jul 16, 2024 - Jul 18, 2024Saskatoon, Saskatchewan