Performance packaged.

Strong at heart.

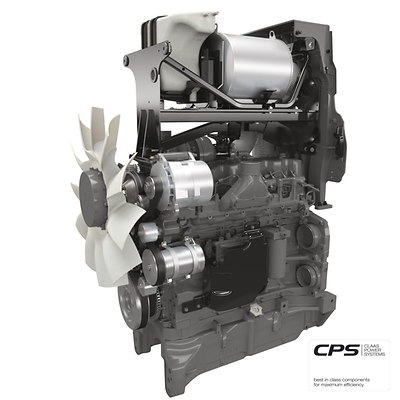

A 6-cylinder, 6.7 liter FPT (Fiat Powertrain Technologies) NEF 6 engine gets to work under the hood. The engine meets the requirements of the T4F emissions standard by incorporating exhaust gas aftertreatment with urea. It uses the latest common rail 4-valve technology, charge-air cooling, and a variable geometry turbo (VGT).

Constant output.

The CLAAS-specific engine performance curve provides full torque in a wide engine speed range, guaranteeing constant output and power delivery when they are needed. This makes it easy to save fuel while working at a low engine speed and maximum torque with the ECO PTO, or to work at rated speed with a full reserve.

- Variable geometry turbo.

The VGT turbo delivers optimum charge-air pressure at any engine speed. It adjusts to load and engine speed, making 70% of maximum torque available even when idling. Optimized combustion therefore means low fuel consumption and maximum performance.

- AXION 880 CMATIC.

The AXION 880 CMATIC delivers up to 290 hp thanks to the intelligent CLAAS POWER MANAGEMENT (CPM) electronic control system. Additional boost power is available for PTO work above 4.3 mph, for transport operations, and also for the fan drive, significantly increasing the performance and versatility of the AXION 880 CMATIC.

Cleaning up.

SCR – the urea-based solution.

SCR stands for selective catalytic reduction, a process in which nitrogen oxides are converted into water and pure nitrogen. This is achieved by using a synthetic aqueous solution of urea (DEF), which is carried in an additional tank. Exhaust gas aftertreatment enables the combustion process in the engine to function at the optimum level.

Fully integrated SCR system.

When designing the AXION 800 Series, all the components required for exhaust gas aftertreatment were considered from the outset. The diesel oxidation catalytic converter (DOC) is positioned under the hood for optimum performance and improved visibility.

CLAAS CMATIC. Continuously variable.

Efficient and user-friendly.

CMATIC is the continuously variable transmission technology used in CLAAS tractors. In the AXION 800 Series, a ZF Terramatic transmission provides efficient conversion of

engine power. In this split-power, continuously variable transmission, the four mechanical ranges are automatically selected by multi-disc clutches. There is no need to shift between ranges manually.

The high mechanical component in the power transmission provides outstanding efficiency and low fuel consumption in every speed range.

- Exploiting real potential.

The available power of the transmission can be used effectively at speeds from 0.03 to 31 mph. The high level of mechanical power transmission also delivers outstanding driving force in reverse. What's more, every gear ratio can be used at every engine speed, giving AXION 880-810 tractors enormous potential for use all year round.

If your foot is not on the accelerator, the transmission is in powered zero mode and maintains its position without creeping or rolling. This means that the tractor can start up safely and easily at steep field entrances or road junctions, even with a full load.

- Superior transmission control.

Powerful acceleration, smooth deceleration, and a fast response to changes in load: CMATIC powertrain management shows its maturity in all conditions and for every task. Stay relaxed and focused throughout the work day so you can concentrate on more important things – CMATIC does the rest for you.

CMATIC. Optimized settings.

Simple, straightforward operation.

The CMATIC transmission has three operating modes: accelerator pedal, drive lever, and manual mode.

In the first two modes, forward speed can be controlled by the accelerator pedal or drive lever. The engine speed and transmission ratio are adjusted automatically – for optimum efficiency and optimized fuel consumption. In manual mode, the driver chooses the engine speed and transmission ratio. Automatic engine and transmission control is not active.

- Engine droop at the push of a button.

The engine droop value can be used for quick and easy regulation of the engine speed under full load. The CEBIS or CIS+ terminal clearly displays the engine speed at which the transmission adjusts.

Two engine droop values can be saved for engine droop in accelerator pedal and drive lever mode. They are retrieved by the quick-access facility using the F buttons. With these values, known as "Eco" and "Power," the droop can be rapidly adjusted to the task in hand, e.g. when moving from the road to the field. The engine droop for the engine speed memory is defined separately. - Tailor-made speed ranges.

With the CMATIC transmission, three speed ranges can be pre-selected in both directions of travel. The active range is displayed in the CEBIS or CIS+ terminal and can be changed at the touch of a button while the tractor is in motion. The lower the maximum preset value for the range, the more accurately the speed can be controlled.

A cruise control speed can be saved for all the ranges while the tractor is moving by pressing the button on the drive lever. The cruise control speeds can also be pre-set on the CEBIS or CIS+ terminal.

HEXASHIFT. For maximum efficiency.

The HEXASHIFT powershift transmission from CLAAS.

With HEXASHIFT you can shift effortlessly through all six powershift speeds and the four automatic ranges using your fingertips, or you can shift automatically using the HEXACTIV auto-shift function.

- Clear benefits.

- No need to use the clutch when changing range

- Excellent efficiency in the field and on the road for low fuel consumption

- CLAAS powertrain management for smooth changes in range and powershift operations

Powershift transmission functions:

- SMART STOP: stop with the brake pedal without using the clutch

- HEXACTIV auto-shift function with cruise control

- Disable cruise control and engine speed memory using the throttle pedal

HEXASHIFT. Always in the right gear.

Automatic transmission control.

There's no need to move through every gear (as in a conventional powershift transmission) when shifting between ranges – the HEXASHIFT transmission automatically selects the most appropriate gear depending on forward speed and load, regardless of whether you are driving manually or automatically. If you press the clutch in range D, the transmission automatically adjusts the powershift speed when the clutch is re-engaged. This can be very useful, e.g. when approaching a road intersection.

- Intelligent transmission settings.

When using the clutchless reverser, you can even change gear automatically when you want the forward speed to be different from the reverse speed. At the headland, you can also engage a pre-selected gear simply by pressing a button. This means that you are always moving at the same speed on the headland. The aggressiveness of the REVERSHIFT clutchless reverser is also adjustable in nine steps (-4 to +4), providing optimum ride comfort in all situations.

- HEXACTIV start-up and approach gears.

The start-up gear engaged when starting the engine is freely selectable between A1 and D1. The specified start-up gear is engaged every time you start the engine. A separate approach gear can also be selected when operating with the HEXACTIV auto-shift function activated. This gear is automatically engaged as soon as the tractor comes to a standstill.

PTO. All choices in one.

The right speed every time.

The PTO speed is easily pre-selected at the touch of a button. Another button on the armrest activates the PTO.

Automatic PTO engagement/disengagement is activated at a specified linkage height which is continuously adjustable. To save the height, you just move the rear linkage to the required position and give a long press on the automatic PTO button.

The integral freewheel on the rear PTO makes implement hitching simple.

Rotational speeds:

- 1,000 rpm at 1,930 engine rpm

- 1,000 rpm ECO at 1,524 engine rpm

- 540 rpm ECO at 1,595 engine rpm

Standing start.

The 1,000 rpm PTO reaches its full speed precisely in the maximum engine output range. As a result, even heavy PTO-driven implements are no problem for these tractors.

In ECO PTO mode the engine runs at a low, fuel-efficient speed. During light work, the lower engine speed can reduce noise levels and save valuable fuel.

Easy shaft changes.

Switching PTO shafts is easy and mess-free. Simply loosen the cap screws, remove the stub shaft, place the new stub shaft on the locating pins, and reinstall the cap screws by securing tightly. No oil leakage occurs, and there are no snap rings to get lost or corroded.

Hydraulics. Powerful, adaptable, efficient.

Pressure-free connections and no mess.

All ten hydraulic couplings at the rear of AXION 880-810 tractors have release levers, so they can be connected and disconnected even under pressure.

Colored markings on the inlet and outlet sides make it easier to attach implements correctly. Oil leakage lines collect the oil from the couplings when attaching and removing connectors.

- Hydraulics that get the job done.

- Load-sensing hydraulic system for all AXION 800 models with 39.5 gpm output

- With CIS+: up to six electronic spool valves can be operated from the armrest – up to four of these with the ELECTROPILOT

- With CEBIS: controls for up to seven electronic spool valves on the armrest – four of which can be operated by ELECTROPILOT. Thanks to free assignment and prioritization of the spool valves, every driver can adapt CEBIS operation according to the task in hand and personal preference. The frequently-used hydraulic functions are positioned side by side for smooth operation.

- With CEBIS and CIS+: spool valve operation can be assigned to the F buttons on the CMOTION, multifunction armrest, or ELECTROPILOT to lighten the workload during combined operating processes

The rear linkage.

Direct adjustment.

The main rear linkage functions are directly accessed via push buttons and dials on the right-hand B-pillar:

- Manual lift and lower for machine attachment

- Vibration damping on/off

- Lock rear linkage

- Activate slip control

- Lifting height limiter

- Lowering speed

- Draft and position control

- Adjustment of wheel slip control

- Lift capacity.

With a maximum lifting capacity of over 21,000 lbs, these tractors can carry the heaviest of implements.

- Wheel slip control via radar speed

- Hydraulic top link

- Excellent view of linkage and drawbar

- Both fenders are fitted with external controls for the rear linkage, PTO, and one of the spool valves (CEBIS only)

Front linkage and front PTO.

Greater versatility.

All models feature an optional front linkage and front PTO:

- Three positions for the front lower links: folded up, fixed working position, and float position in slotted hole

- Double-acting lift rams as standard

- Short distance between front axle and mounting points for improved guidance of front attachments

- 1,000 rpm PTO

- External control of the front linkage and one double-acting spool valve in the CEBIS version if fitted

- Maximum lift capacity of over 10,000 lbs

Precise work.

The optional front linkage position control system for the CEBIS version enables front-mounted implements to work extremely accurately. The working position is adjusted via a rotary knob on the armrest, while the lifting height can be limited and the lifting and lowering speed can be set using CEBIS. The front linkage can be used in single- or double-acting mode.

Always connected.

Optional hydraulic and electronic interfaces for many applications are incorporated into the front linkage:

- Up to two double-acting spool valves

- Free-flow return line

- 7-pin socket

- ISOBUS socket

Fast, straightforward maintenance.

Good access saves time and money.

Daily maintenance work should be as straightforward as possible – because we know from experience that nobody enjoys doing things that are complicated or inconvenient.

- The hood opens at the press of a button, providing access to all the engine maintenance points

- The engine oil can be checked and topped off on the left-hand side of the tractor when the hood is closed

- All daily maintenance tasks can be carried out without tools

- The front axle lubrication points are located in front of the radiator assembly for optimum accessibility

- The fuel prefilter is conveniently located by the left-hand cab access ladder

- Large drawer in the left-hand access ladder with space for a standard toolbox

The long oil-change intervals (engine 600 h, transmission and hydraulics 1,200 h) save time and money. As a result, less valuable working time is lost during the season and the tractor is where it should be – at work.

Fresh air for full power.

The large intake panels in the hood provide plenty of fresh air for cooling and for the engine air filter. Low flow rates at the intake panels help them to stay clean and permeable at all times.

The radiator assemblies are supported by a robust frame and gas-filled shock absorbers open the radiator panels to two positions for thorough cleaning. Cleaning can therefore be carried out safely and conveniently as required.

The air filter is accessibly located in the cool zone in front of the radiator panels so it can be removed without hindrance. Coarse dirt particles are extracted in the filter housing, further extending the cleaning interval.

Event calendar

-

DateEvent

-

Jul 25, 2024 - Jul 25, 2024Baltic, SD

-

Aug 27, 2024 - Aug 29, 2024Boone, IA

-

Jul 16, 2024 - Jul 18, 2024Saskatoon, Saskatchewan