JAGUAR “assistance systems” prove worth in university trial.

Anyone who has ever harvested forage crops knows that there is a LOT happening in the cab of a forage harvester. From the driver’s seat, the operator must coordinate logistics, read the terrain, watch the weather, mind the crop conditions, manage the assistance systems, optimize machine output, and direct the crew . . . seemingly all at the same time. It is a stressful endeavor even for the most experienced drivers.

Recently, Cologne University of Applied Sciences in cooperation with CLAAS Global Sales studied the influence and effects of the JAGUAR operator assistance systems on both the operator and the machine. Three assistance systems were evaluated to determine what (if any) advantages they provided:

- Automatic Steering Systems: CAM PILOT for pickup work and GPS guidance for standing crops.

- Automatic Trailer Filling: AUTO FILL technology controlling crop discharge.

- Automatic Machine Management: CEMOS AUTO PERFORMANCE utilized to control engine output and travel speed.

The Physical Effects on the Operator:

Four different parameters were evaluated to determine the physical effects on the operator:

- Control lever deflection and control of the upper discharge chute (establish via CAN bus data)

- Heart rate (established via fitness tracker)

- Steering wheel movements (established by CAN bus data)

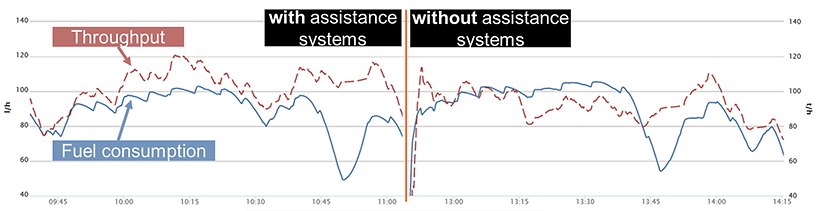

- Throughput and fuel consumption (established via CLAAS TELEMATICS / internal job management

Psychological Effects on the Operator:

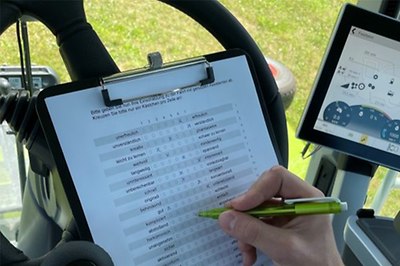

The operators involved in the study completed an internationally recognized User Experience Questionnaire (UEQ). The academic questionnaire was completed after every trial (with and without operator assistance systems) to assess the user experience based on 26 attributes. The questionnaire focused on the appeal, efficiency, comprehension, dependability, originality and stimulation of the operator experience.

Results:

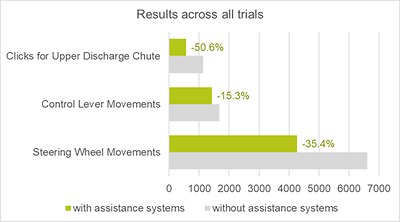

Across all trials, operators using the operator assistance systems experienced . . .

- 50.6% fewer clicks for control of the upper discharge chute

- 15.3% fewer movements of the control lever

- 25.4% fewer turns of the steering wheel

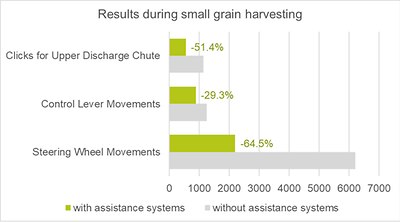

During small grain harvesting, operators using the operator assistance systems experienced . . .

- 51.4% fewer clicks for control of the upper discharge chute

- 29.3% fewer movements of the control lever

- 64.5% fewer turns of the steering wheel

Physical Impact:

The effect of the operator assistance systems on the heart rates of the participants showed a lower or equal heart rate in 10 of the 12 participants. In one of the small grain harvesting trials, those with operator assistance systems experienced an average mean of 71-80 bpm, while the average mean was 91-100 bpm without the assistance systems.

Psychological Impact:

Perhaps even more telling were the results of the UEQ surveys conducted after each trial. In all six categories, the surveys revealed a preference for the operator assistance systems. The largest impact was discovered in the areas involving attractiveness and novelty. Manual operation was rated negatively in both of these categories.

Bottom Line Impact:

In addition to happier, less stressed drivers, the study showed a significant and positive effect on operating performance. While using the operator assistance systems, the JAGUAR forage harvester experienced greater productivity and efficiency:

- 13% less fuel consumption measured in l/t

- 10% higher throughput in t/h