Straight and fast. The crop flow.

Maximum throughput with low power consumption.

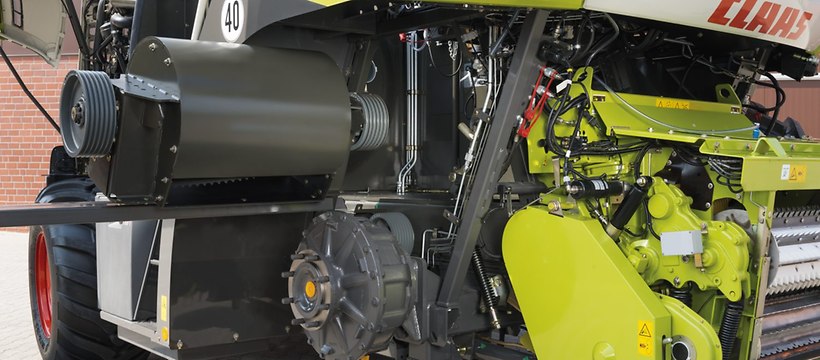

An optimal crop flow is a major factor in determining the daily output. The crop flows in a straight line through the entire machine without any awkward angles. It doesn't matter if you are harvesting grass without the Corncracker or are working in corn silage with it engaged. The crop is accelerated further at each step and is centered increasingly by the chevron arrangement of the knives and accelerator paddles. This results in maximum performance with minimum power consumption and makes for highly reliable operation. The JAGUAR demonstrates this time after time: with outstanding results – measured in terms of fuel consumption per ton.

1 Intake

- Robust with perfect precompression

2 V-CLASSIC chopping cylinder

- Precise cutting for excellent chop quality

- Chopped material is centered for low wear

3 Corncracker

- Optimal crop processing

- Extended MULTI CROP CRACKER range

4 Accelerator

- Chopped material is centered for reliable transport

- Mechanically adjustable clearance

Powerful and reliable. The intake.

Robust rollers.

The intake roller drive in the JAGUAR is designed for extremely high performance. Six cutting lengths can be set as required. Robust compression rollers ensure an optimum crop flow. Additional wear bars reduce wear to the machine.

Hydraulic reverser.

The hydraulic reverser ensures a slow, controlled and sensitive reverse rotation. The crop is gently extracted from the intake. When used with the PICK UP, the roller crop press is raised automatically, and, if required, the auger as well. With incremental reversing, foreign objects are brought to the intake rollers, where they can be removed quickly and safely.

Sensitive metal detector.

The metal detection system installed in the front feed rollers locates any magnetic object in good time. The low-wear, quick-stop mechanism then stops the intake immediately. Thanks to the location display in CEBIS, the operator can quickly see where the magnetic metal object is to be found.

STOP ROCK stone detector.

A powerful and rugged intake drive is one thing, but full protection against foreign objects is another. The STOP ROCK stone detector increases the reliability of the JAGUAR. If it detects a stone in the windrow, it stops the intake immediately. You can set the minimum stone size yourself – the sensitivity is conveniently adjustable from the cab using CEBIS.

The chop length can be doubled by equipping the V-CLASSIC cylinder with half-knives. The half-knives enable a very consistent crop throughput which is ideal when harvesting grass or corn for long chopping and SHREDLAGE®.

Precise and proven. The V-CLASSIC chopping cylinder.

Chevron-shaped knife layout.

The effectiveness of the 750 mm wide chopping cylinder in the JAGUAR is unique. The chevron-shaped knife arrangement produces a pull-through, guillotine cut with minimum effort. At the same time, the forage is guided towards the middle – this reduces wear and friction losses on the sides of the drum housing.

- Robust design

- Minimum power requirement

- High throughput

- Top chop quality

- Excellent discharge

| Cylinder | Application | Knife set - full | Knife set - half | Half-knives |

| V-CLASSIC 20 | Knife set | 20 = 2 x 10 | 10 = 2 x 5 | 20 = 2 x 10 |

| Chop length | 5 / 6.5 / 8.5 / 11 / 17 / 21 | 10 / 13 / 17 / 22 / 34 / 42 | 10 / 13 / 17 / 22 / 34 / 42 |

Fully automatic sharpening.

A precision chop and consistent chop quality are possible only if the blades are absolutely sharp. The sharpening of the knives is controlled from the cab.

You can also control the shear-bar setting from the cab. The shear bar does not need to be loosened for this operation; instead, the mounting block is pivoted and moves gently towards the chopping cylinder with the shear bar firmly fixed on top. Knock sensors register contact and set the shear bar accordingly.

Sharpening and adjustment of the shear bar should be carried out on the basis of the throughput quantity rather than at a given time of day. CEBIS can be configured to give a reminder when knife sharpening is required.

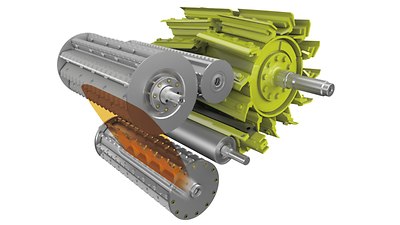

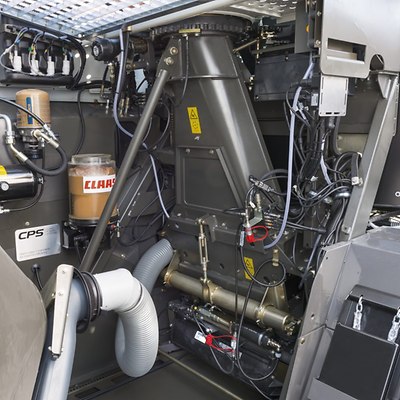

MULTI CROP CRACKER.

The key characteristics of the MULTI CROP CRACKER (MCC) are its rugged construction and its extremely well sealed housing. Its great advantage is its flexibility. The outstanding accessibility of the rollers allows them to be replaced by others quickly.

- MCC L.

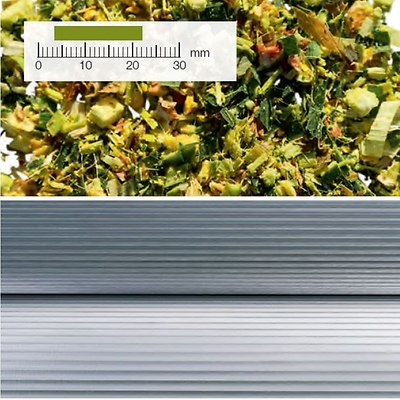

MCC L

The conventional MCC L is equipped with the familiar sawtooth profile and operates as standard with a speed differential of 30%. This system is used successfully for harvesting silage as feed for dairy cattle (long) and for feeders. Other rollers with a different number of teeth are used in crops where there is a greater need for more processed silage. The required degree of silage processing is achieved by increasing the speed differential.

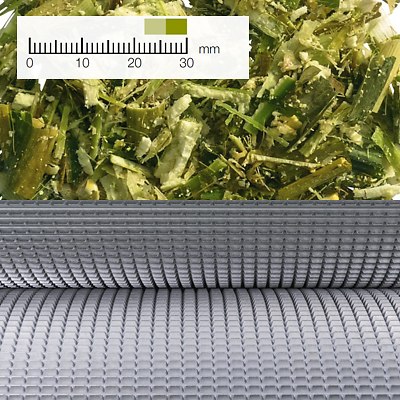

- MCC SHREDLAGE®.

MCC SHREDLAGE®: extremely long chop lengths from 26 to 30 mm

SHREDLAGE®, a technology which was developed in the US and for which CLAAS has now acquired the licence, is an intensive corn silage conditioning system in the extremely long chop length range of 26 to 30 mm. Operating with a speed differential of 50%, the Loren Cut® rollers have a sawtooth profile into which a counterdirectional spiral groove has also been cut. In this way, the MCC SHREDLAGE® is able to grind the corn kernels thoroughly and chop up the cob fragments completely.

Leaves are well shredded and the stalk material in particular is subjected to a lateral effect by the spiral groove which causes the bark to be rubbed off the stalk. At the same time, the soft inner core is split lengthways.

Dynamic and exceptionally accessible. The crop accelerator.

Acceleration the energy-saving way.

The accelerator is ideally positioned in the JAGUAR for optimum performance of its task of speeding up the crop flow and feeding the crop reliably. The chevron-shaped accelerator paddles center the crop flow, reducing the wear on the side walls of the discharge chute. As the crop flow does not have to negotiate any awkward angles, correspondingly little energy is required to move it.

For heavy crops, the clearance between the accelerator rear wall can be adjusted with optional mechanical turnbuckle. By increasing the gap in heavy crops like corn silage, less power is required by the accelerator.

Continuous and precise. Throughput measurement.

Throughput measurement with the QUANTIMETER.

By recording the deflection of the upper rear precompression roller, together with the intake width and intake speed parameters, the volume flow is measured continuously. Counterweighing is recommended in order to ensure the highest possible degree of accuracy (ton per acre).

Dry matter measurement.

Continuous dry matter measurement significantly improves the accuracy of the current throughput measurement.

- The conductivity and temperature of the crop flow are determined in the discharge spout

- CEBIS continuously displays the current dry matter content

- Highly wear-resistant ceramic base plate with metal rings for a long service life

Dry matter measurement with NIR sensor.

Continuous dry matter measurement significantly improves the accuracy of the current throughput measurement.

With 20 measurements per second, the near infrared sensor (NIR sensor) attains a very high degree of precision – ideal for the documentation of harvest data for further use.

- Measuring range for grass: 24-65% dry matter

- Measuring range for WCS: 24-60% dry matter

- Measuring range for corn: 20-60% dry matter

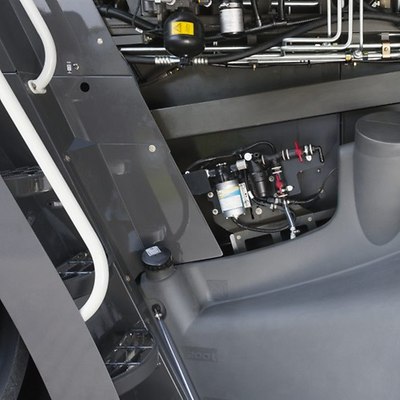

Concentrated and precise. The silage additive systems.

Using additives to enhance silage quality.

Applying silage additives while chopping has become a standard service offered by professional contractors. You can carry up to 99 gal (375 l) of fluid in the standard-fit additive tank which is easy to fill. The mixed additive is sprayed straight into the crop accelerator.

- Tank capacity of 99 gal (375 l)

- Flexible filling and cleaning facility

- Metering from 8 gal/hr to 105 gal/hr (30 l/h to 400 l/h)

- Throughput based metering from 0.13 gal/t to 0.53 gal/t (0.5 l/t to 2 l/t) (up to 200 t/h)

- Dosage on basis of dry matter possible

- Sight tube for external level indication

The dosage is controlled via CEBIS. Furthermore, CEBIS informs the operator about the fill level of the tanks.

ACTISILER 20 for precise dosage.

There is currently a trend towards a reduced quantity and a higher concentration. The new, optional ACTISILER 20 has been designed specifically to achieve this high-precision task with a precisely metered quantity of concentrated lactic acid bacteria solution. The control of the dosage, the record of how much you apply and the monitoring functions are all easily managed using CEBIS.

- Separate 5.2 gal (20 l) tank for highly concentrated lactic acid solution

- Dosage is controlled via CEBIS:

Constant: 6.75 to 253 fl oz/hr (200 ml/h to 7500 ml/h)

Throughput-based 0.34 to 1 fl oz/t (10 ml/t to 30 ml/t)

- Dosage on basis of dry matter possible

Both systems can also be used simultaneously.

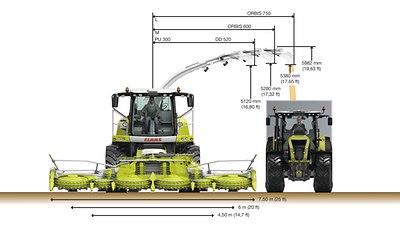

The discharge spout. Modular design.

High strength and a low dead weight are the key characteristics of the discharge spout. The concentrated crop stream can be directed more reliably, minimizing wasteful losses. The modular design enables the system to be rapidly adjusted to different working widths. Two extensions (M / L) allow operation up to a working width of 25 ft (7.5 m). The back of the discharge spout is entirely bolted: as a result, the top plates also function as wear plates.

OPTI FILL. Extremely user-friendly.

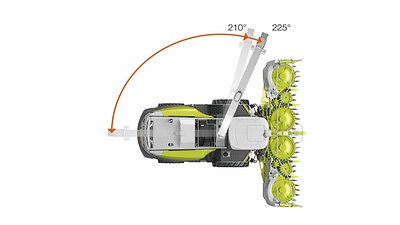

The OPTI FILL optimized spout control system makes management of the transfer process extremely easy. The wide swivel angle of up to 225° allows an optimal view of the transfer process. When the discharge spout is swiveled, the end flap is adjusted automatically so that the transfer process takes place parallel to the direction of travel. Two permanently programmed spout positions simplify the swiveling process at the end of the field, e.g. when chopping up and down along one edge of a field. Furthermore, the discharge spout can be returned to its parking position automatically at the touch of a button.

AUTO FILL. Right on target - now also to the rear.

AUTO FILL. Automatic filling of transport vehicles.

AUTO FILL is based on digital 3D image analysis. The system takes care of controlling the discharge spout for you.

NEW: AUTO FILL "Side Rear".

With the "Side Rear" AUTO FILL function, automated discharging from the forage harvester is now possible not only to the side but also to a trailer behind the forage harvester – perfect when starting chopping or dividing fields. In chopping start-up mode, you can easily choose whether you wish discharging to take place to the side or the rear. For automatic filling to the rear, only the desired impact point needs to be specified.