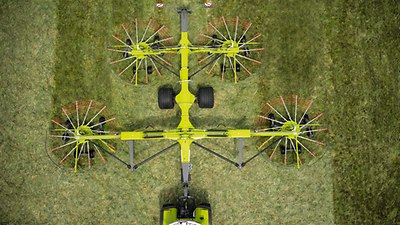

Professional grade raking.

Keeping the forage harvester operating at full capacity is no small task. To eliminate bottlenecks in the harvesting chain, invest in the rake built with maximum capacity and minimal downtime in mind. Operators appreciate carrying out all machine functions from the comfort of the tractor cab. Even unskilled operators will find it a breeze to make perfectly shaped windrows that maximize both rake and forage harvester throughput.

Fine-tuned control.

On the LINER 4900 and 4800 front booms telescope individually for seamless operation around corners and field obstacles. Swath width is controlled from the terminal along with tine height adjustment. Furthermore, each boom raises and lowers individually, allowing for clean headland management in irregularly shaped fields.

ISOBUS functionality.

With operator comfort in mind, control of the LINER 4900 and 4800 BUSINESS is carried out entirely from the operator seat. Using the standalone CEMIS 700 or CEMIS 100 (not shown) is possible or further integration is possible with a tractor ISOBUS monitor, a standard feature on most CLAAS AXION tractors (shown).

Optional six wheel rotor chassis.

Optional six-wheel rotor chassis on all four rotors ensures rotors follow the ground closely to not skip crop but also react to changing ground contours quickly. The massive footprint keeps ash out of the raked crop to maximize feed value along with keeping the rake moving across tough pivot tracks.

Optional working lights.

Keep operators focused and productive with optional integration of rake working lights. Switching on tractor lights also activates the work lights to illuminate the crop entering the rotors and the completed swath behind the machine. This allows full utilization of the machine's capacity even into long working nights.

FOUR ROTOR RAKES

LINER | 4900 BUSINESS | 4800 BUSINESS | |

Working width | ft (m) | 33' 1" - 49' 2" (10.1 - 15.0) | 30' 6" - 44' 7" (9.3 - 13.6) |

Hitch type | 2-pt trailed | 2-pt trailed | |

Mounting category | III | II | |

PTO shaft speed | RPM | 540 | 540 |

Number of rotors | qty | 4 | 4 |

Rotor diameter | ft (m) | 12' 6" (3.8) | 11' 6" (3.5) |

Tine arms per rotor | qty | 14 | 12 |

PROFIX tine arm | ● | ● | |

Windrow laying position | Center | Center | |

Windrow width | ft (m) | 4' 7" - 8' 2" (1.4 - 2.5) | 4' 7" - 8' 2" (1.4 - 2.5) |

Tine height adjustment | Electrohydraulic | Electrohydraulic | |

Hydraulic transport lock | ● | ● |

● Standard ○ Optional – Not available