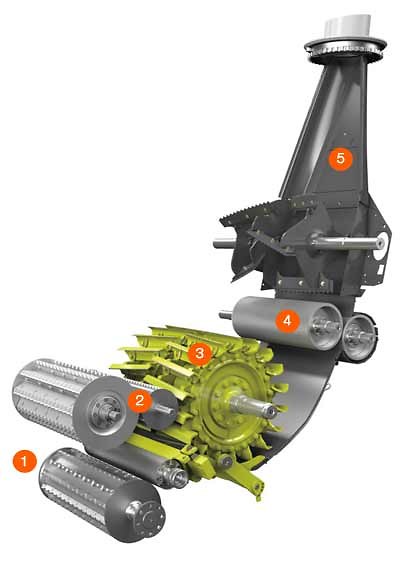

The crop flow. Straight and fast.

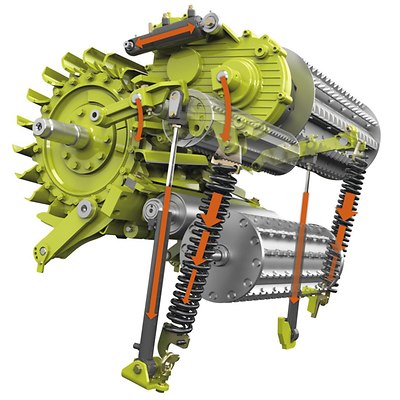

1. Header

- Variable front attachment drive enables consistent crop flow from front attachment and intake for consistently high chop quality

2. Intake

- Intake rollers with an opening of up to 7.1 in (180 mm) for high throughput

Hydraulic precompression (optional) for excellent chop quality

- Chopping cylinder is easily accessible thanks to QUICK ACCESS

3. V-MAX knife drum

- V-MAX knives are attached to the cylinder by tightening the bolts until they lock; no adjustment is necessary

4. MULTI CROP CRACKER

- The right arrangement for a high-quality processing result

5. Flexible acceleration

- Accelerator clearance can be set from the cab, ease of operation for high efficiency

The Corncracker.

Optimal processing.

The requirements for silage chop length and processing differ widely depending on the individual farm and the purpose for which the silage is to be used. The spectrum extends from extremely short chop lengths of between 3.5 and 12 mm all the way up to the SHREDLAGE® process with lengths greater than 25 mm.

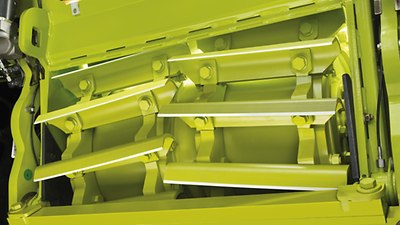

MULTI CROP CRACKER.

The key characteristics of the MULTI CROP CRACKER (MCC) are its rugged construction and its extremely well sealed housing. Its great advantage is its flexibility. The outstanding accessibility of the rollers allows them to be replaced by others quickly.

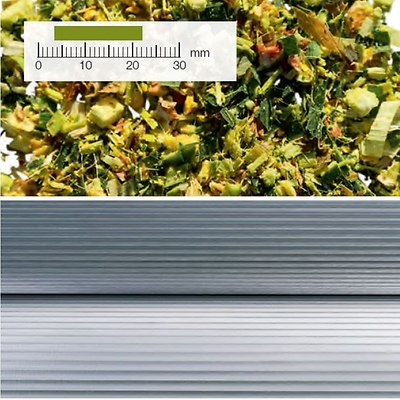

- MCC L.

MCC L

The conventional MCC L is equipped with the familiar sawtooth profile and operates as standard with a speed differential of 30%. This system is used successfully for harvesting silage as feed for dairy cattle (long) and for feeders. Other rollers with a different number of teeth are used in crops where there is a greater need for more processed silage. The required degree of silage processing is achieved by increasing the speed differential.

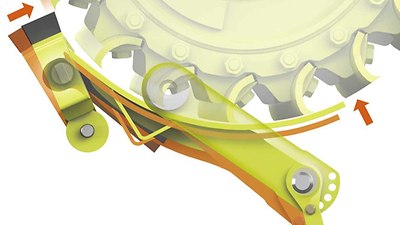

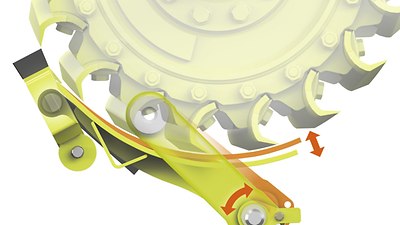

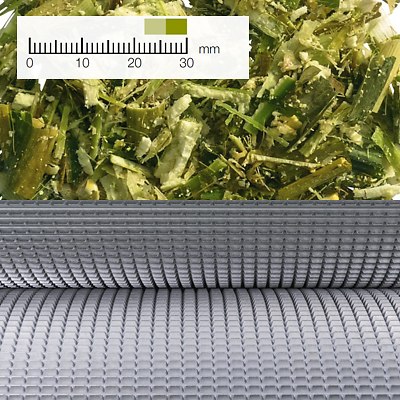

- MCC SHREDLAGE®.

MCC SHREDLAGE®: extremely long chop lengths from 26 to 30 mm

SHREDLAGE®, a technology which was developed in the US and for which CLAAS has now acquired the licence, is an intensive corn silage conditioning system in the extremely long chop length range of 26 to 30 mm. Operating with a speed differential of 50%, the Loren Cut® rollers have a sawtooth profile into which a counterdirectional spiral groove has also been cut. In this way, the MCC SHREDLAGE® is able to grind the corn kernels thoroughly and chop up the cob fragments completely.

Leaves are well shredded and the stalk material in particular is subjected to a lateral effect by the spiral groove which causes the bark to be rubbed off the stalk. At the same time, the soft inner core is split lengthways.

AUTO FILL. Right on target - now also to the rear.

AUTO FILL. Automatic control of the discharge spout. Now also with rear discharging.

AUTO FILL is based on digital 3D image analysis. The system takes care of controlling the discharge spout for you. With AUTO FILL, discharging to the rear is now also automated.

In the past, the AUTO FILL function enabled automated discharging from the forage harvester to a trailer running alongside. With the new "Side Rear" AUTO FILL function, automated discharging from the forage harvester is now possible not only to the side but also to a trailer behind the forage harvester – perfect when starting chopping or dividing fields.

In chopping start-up mode, you can easily choose whether you wish discharging to take place to the side or the rear. For automatic filling to the rear, only the desired impact point needs to be specified.

For the AUTO FILL variant, the JAGUAR is equipped with LED swivelling spout lighting. This means that it is also possible to work in the dark

while reducing the operator's workload.

CLAAS PREMIUM LINE. Good for 1,500 hours. Guaranteed.*

Basic

Advanced

Professional

Harvesting represents a considerable challenge for both farmers and their machines. Long working days are the rule. When the work has to be completed as quickly as possible, there is little time available to replace wear parts. CLAAS PREMIUM LINE parts provide very high wear resistance and a long service life, so that in many cases it is not necessary for them to be replaced until after the harvest campaign. Further information >