The drive. Best in class.

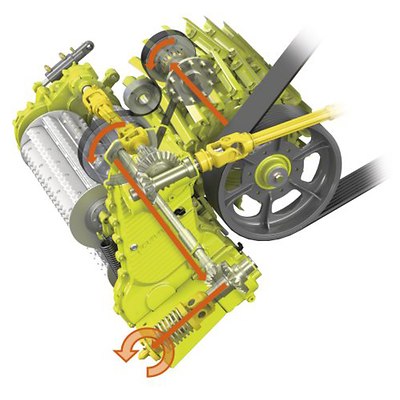

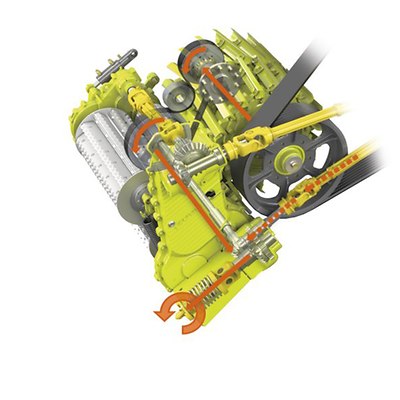

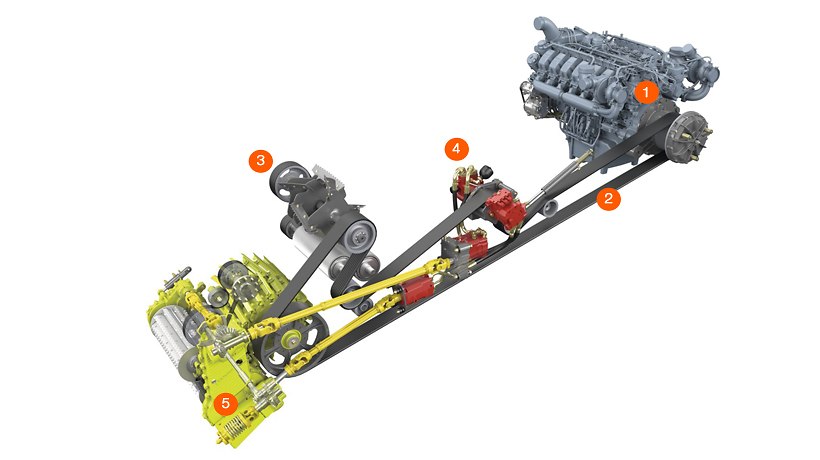

Tough, reliable and low-maintenance. Five features guarantee top efficiency:

- Transverse-mounted engines

- Direct powerband drive between the engine and the chopping unit, the accelerator and the COMFORT CUT intake roller drive

- The corncracker is driven directly from the accelerator by a powerband

- QUICK STOP – active braking brings the crop flow to a halt quickly when the main drive is disengaged

- The possible front attachment drive types:variable, split-power, standard

The JAGUAR drive line.

The JAGUAR power flow is quite simply the most efficient design on the market. The chopping mechanism is driven directly from the engine's crankshaft via a long, maintenance-free powerband. This design is still unmatched even today, many years after it was developed.

- The precompression roller drive is integrated into the main drive line

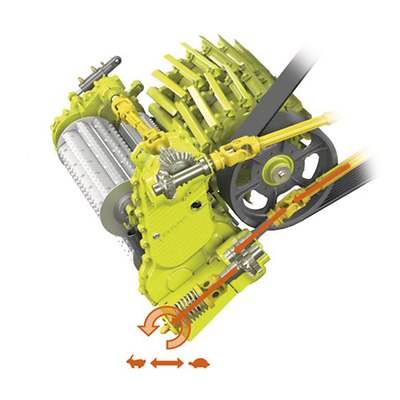

- Thanks to the COMFORT CUT precompression roller drive, the operator can adjust the chop to any required length from the comfort of the cab while the machine is underway

- The whole intake is designed for maximum reliability, outstanding durability and a long service life, with rugged drives, large bearings and gears

- The front attachments are attached to the JAGUAR by means of a quick coupling and can be driven in standard, split-power or variable mode

Variable header drive. Something for everyone.

3. Hydraulic header drive.

- For ORBIS corn headers and PICK UP

- All-hydrostatic drive

- Optimal crop flow between header unit and intake elements, manual or automatic speed adjustment to the preset chop length with low power requirement

- High efficiency

Efficient main drive train.

Like the COMFORT CUT infinitely variable chop length adjustment which can be automated, the variable header drive is integrated into the main drive train. The advantage of this arrangement is that, in the event of any speed variations, the header drive, the intake drive, drum speed, accelerator and corncracker are affected equally. This results in a constant chop length at all times.

Two-stage reversing with hydrostatic front attachment drive.

Two-stage reversing is possible in combination with the CMOTION control lever. Either the front attachment is reversed alone, or the front attachment and the intake are reversed together.

Hydraulics and electrics. Clear layout.

Hydraulics control.

The spool valves are clearly laid out on the left side of the machine. Proportional valves for the discharge spout and front attachment control system allow a smoother response when these systems are functioning automatically. In order to enable a consistent stubble profile, even when operating at very high ground speeds, the swivel speed of the ORBIS lateral levelling mechanism, for example, can be adjusted as required in CEBIS.

Vibration damping at the headland.

The vibration damping system is activated automatically once the headland is reached and the header is raised past the working height. This additional convenience feature reduces wear and tear on the machine when crossing sprayer wheelings, for example. The header is protected by a correspondingly gentle suspension response.

- Rapid implementation of function commands

- Efficient control by proportional valves

- Cost-effective maintenance thanks to low-volume oil system

Easy-maintenance electrical system.

A straightforward, convenient control concept demands a fast, reliable electrical system. In the JAGUAR, all the key components are housed securely and centrally in the cab. An expansion box in the maintenance compartment of the JAGUAR allows the easy accommodation of additional options when retrofitting:

- PROFI CAM

- AUTO FILL

- ACTISILER 20

- NIR sensor

- QUANTIMETER

- Auxiliary diesel tank,79 gal (300 l)

- Accelerator gap setting

- Tire pressure regulation system

- DYNAMIC COOLING