The factory of the future

Our tractor factory is located in the town of Le Mans in Northwestern France. 10,000 custom-built machines are produced here each year. Since the “CLAAS Forth” modernization initiative, the site has been a prime example not only of the practical implementation of Industry 4.0, but also of the involvement of the workforce in major projects.

Focus on the people

For 20 years now, most CLAAS tractors have been manufactured at our factory in Le Mans, France. During that time, the production process has continuously evolved.

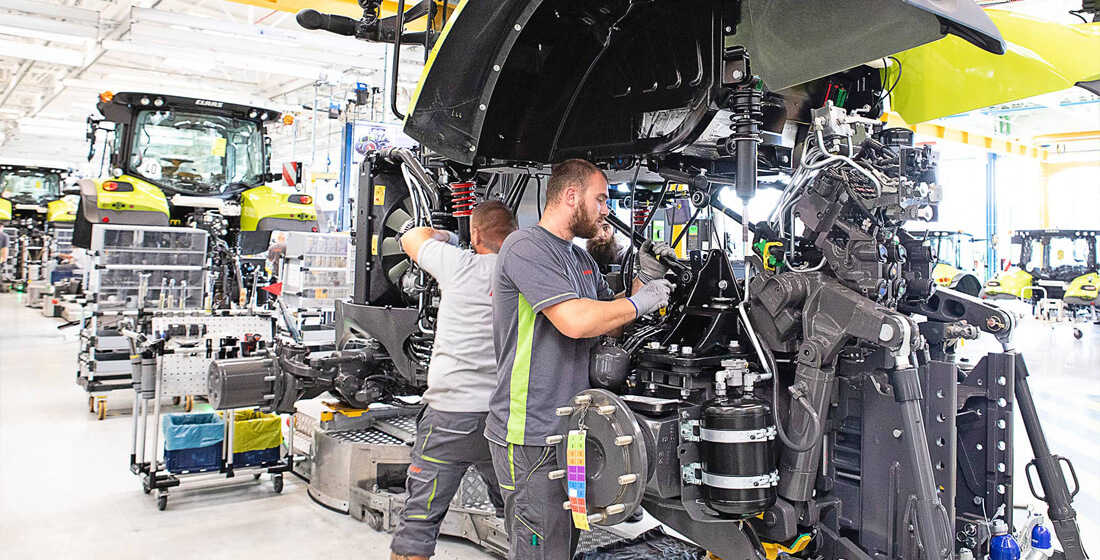

Go to the articleIt’s no ordinary factory. That’s what Romane Niepceron likes about it. “It feels like family working here,” says the 27-year-old assembly line worker. But the CLAAS Industry 4.0 plant in Le Mans is anything but family-like in terms of its size: over 750,000 square feet of covered floor space, 1,000 employees, and 10,000 tractors produced every year.

So what makes it feel so friendly? For Romane Niepceron, it’s all down to the working environment. “The factory is quiet, bright and well lit”, she explains. “And there’s plenty of room to move around.”

Restructuring during ongoing operations

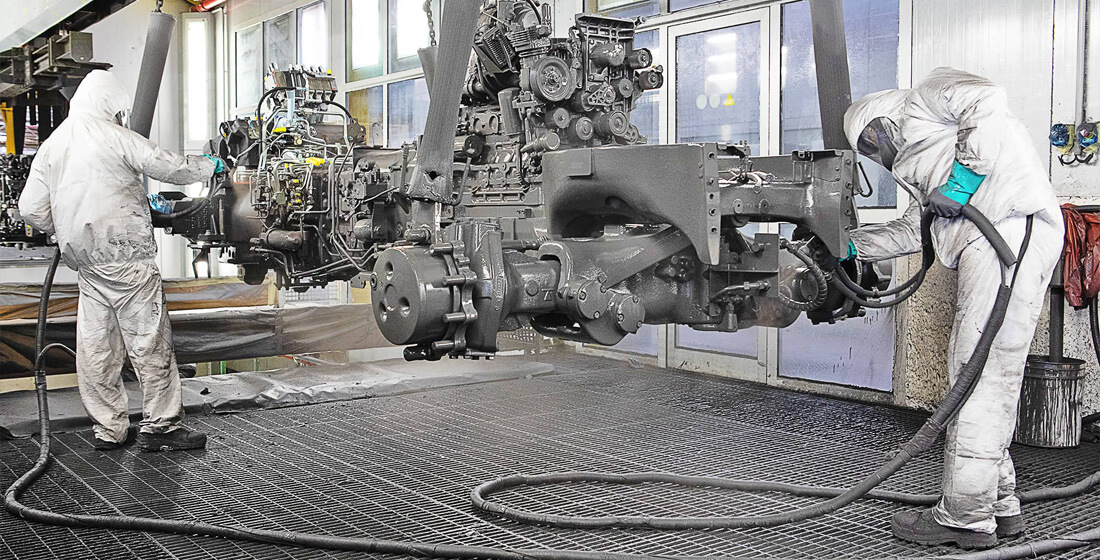

That wasn’t always the case. Before 2017 the factory looked much like any other tractor factory: it was darker and space was cramped; almost like a giant garage. The equipment CLAAS inherited when the company acquired the factory from another manufacturer in 2003 was also in dire need of an upgrade.

The CLAAS Forth project was designed to modernize the site. The goal was to get it right the first time when assembling tractors and minimizing the error rate. The three-year restructuring program, which cost 40 million euros, meant not only replacing the technical equipment, but also an overhaul of all processes—from the internal logistics system to the equipment for filling machines with various fluids.

The challenge was to carry out the restructuring during ongoing operations. Major upgrades without disrupting production operations could only be carried out once a year during the plant’s four-week summer break. This meant that most of the modernization work had to be done alongside day-to-day operations.

The fact that the factory does not have a traditional large-scale production line, despite assembling 50 tractors per day, made this particularly difficult. You see, each tractor is made to order—from a product range of five different models with performance rating range of 72 to 460 hp. The number of possible configurations is so vast that no more than two identical tractors are produced in any given quarter.

Digital planning and driverless transport vehicles

Three factors were key to the successful rollout of the project. Firstly, the modernization was digitally planned. “Our first step was to map the factory and all the associated buildings in a 3D software program”, explains Aldric Pavec, Head of Process Engineering in Le Mans. The 57-year-old was responsible for the CLAAS Forth planning phase. “This allowed us to model the entire restructuring, and then use 3D animations and VR headsets to test live on site whether specific processes could be made even more efficient.”

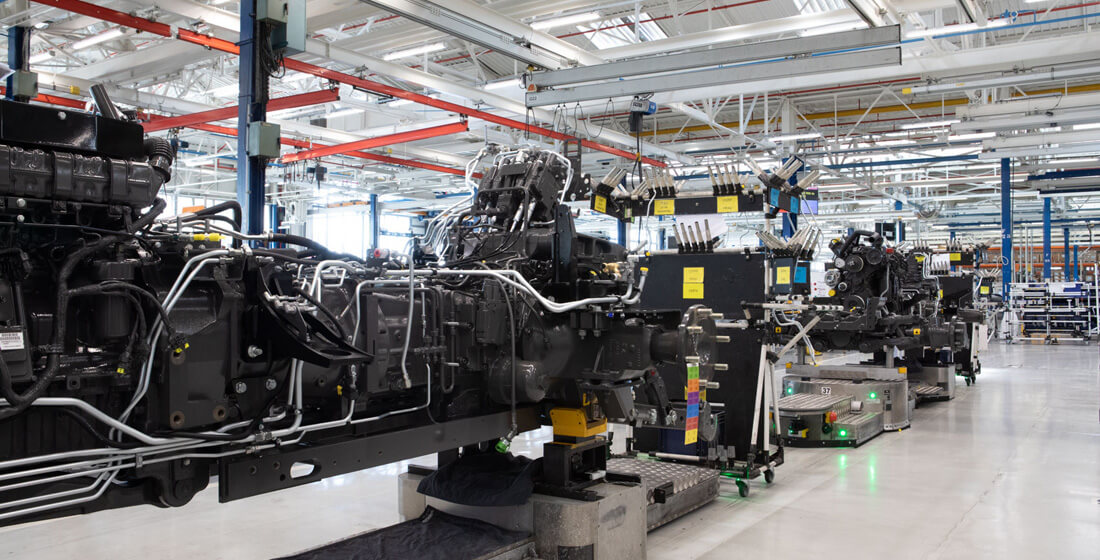

The second factor that enabled us to restructure the factory was the removal of the previous chain conveyor line and replacing it with automated guided vehicles or AGVs. These robots can transport tractors weighing up to 20 t along the 3/4 mile (1.2 km) assembly line from the first station to the last—fully automatically and with flexibly timed sequences.

Sensors on the front cause the machines to brake automatically when obstacles are detected, allowing employees to move safely between the AGVs without risk of injury.

The removal of the chain conveyor line freed up open space on the factory floor for other restructuring work. At the same time, the AGVs made the production process more flexible, which also benefitted the CLAAS Forth project.

Employee involvement

The third and perhaps most important factor in the project’s success was getting the employees onboard and involved. “We really wanted the restructuring to relieve the burden of day-to-day work for the employees”, says Aldric Pavec, Head of Process Engineering. “At the same time, they know the assembly process better than anyone, so it was essential for us to involve them closely in the project.”

This is why there were virtually no outside consultants working on the project. The core team consisted of 50 employees, including engineers, assembly line workers and apprentices. The departments Controlling, HR, Purchasing, Logistics and R&D were also involved.

Employees participated in all phases of the project. They even chose the project name CLAAS Forth. A CLAAS Forth forum open to everyone took place once a week in Le Mans, where employees were informed of changes and the reasoning behind them. In addition, employees were regularly shown how to operate the new systems.

I have often seen assembly line workers in the factory taking selfies.

A multitude of Industry 4.0 elements

Romane Niepceron agrees that involving the employees was worth it. She’s in charge of filling the trolleys that are attached magnetically to the AGVs and used to transport all the bolts and small components required to assemble a specific tractor.

Before the restructuring, Romane Niepceron needed a long list to pick the right parts for the trolley. Now she finds them by scanning the barcodes on the shelves with her gloves. When a light goes on in a compartment, she knows that this is where she’ll find the part or machine element she needs for the trolley.

This system is just one example of the multitude of Industry 4.0 elements in this state-of-the-art factory. Network-integrated tools support operators in a wide range of tasks, from receiving jobs to checking off checklists. The massive warehousing system has been replaced with a space-saving automated small-parts storage system.

The digital assistants are making an impact. The number of cases where a minor assembly error has to be corrected downstream has decreased dramatically: from 200 times to less than once a day. And that’s with tens of thousands of parts assembled daily in Le Mans.

The site’s technical equipment has also impressed the French government, which presented the tractor factory with the “Vitrine Industrie Du Futur” award as an example of an “Industry of the Future”.

“A mixed feeling of pride and trust.”

In an interview, site manager Etienne Bourasseau explains how the tractor factory in Le Mans has evolved.

Interview with Etienne Bourasseau250 tons of new paint

The new, friendlier working environment is also the result of employees’ suggestions: all the walls and the ceiling have been repainted with around 250 tons of white paint and the floors are light gray. Together with the LED lighting, this gives the impression of daylight.

Various actions have been taken to curb noise levels in the factory as well. For instance, the flooring was treated to reduce the noise of transport vehicles, and quieter electric screwdrivers are now used instead of pneumatic air guns. “We recently had a visit from a manager in the semi-conductor industry,” explains Aldric Pavec. “She could hardly believe that tractors could be built in such a clean and quiet environment.”

The changes have gone down very well with the workforce, too. “The employees are very proud of the modernized factory,” says site manager Etienne Bourasseau. “We often hear that they now feel really welcome, and that has improved the workplace culture even further. I’ve often seen assembly line workers in the factory taking selfies.”

Aldric Pavec can confirm this. “We recently conducted interviews to find new assembly line workers,” he explains. “Several candidates had already worked in many other factories in Le Mans. They told us that our factory is now considered to be the best pace to work in the city.”

A day in the life of the Le Mans factory

CLAAS Forth set to continue

The fact that CLAAS Forth has now been extended to other areas of the factory shows how popular it is with employees. Modernization of the assembly hall for tractor cabs has been underway since February 2021—on the initiative of the employees.

The “Cabin Optimization Project” is led by Gilles Drouyer. “This project is closely aligned with CLAAS Forth principles,” says the 30-year-old engineer, who has worked for CLAAS for five years. “Involving employees in the planning is paramount.”

That’s why two skilled workers are permanent members of the project team. Jeremy Legendre is one of them. The 30-year-old works in production and likes his new role. “It’s interesting to see daily operations from another perspective,” he says.

The “Cabin Optimization Project” will be completed in March 2023. “I’m looking forward to seeing the upgrades to our part of the factory,” says Jeremy Legendre.

Like the CLAAS Forth initiative, Gilles Drouyer and Jeremy Legendre’s project is intended to prepare the factory for the future. In the next few years, the company plans to expand production in Le Mans—from the current 10,000 to 13,000 tractors a year.

Romane Niepceron is looking forward to the new developments, too. The 27-year-old has been working at the Le Mans factory for five years and was recently promoted to parts commissioning specialist. “The factory is a good place to develop your career,” she says—another reason why she likes it here.